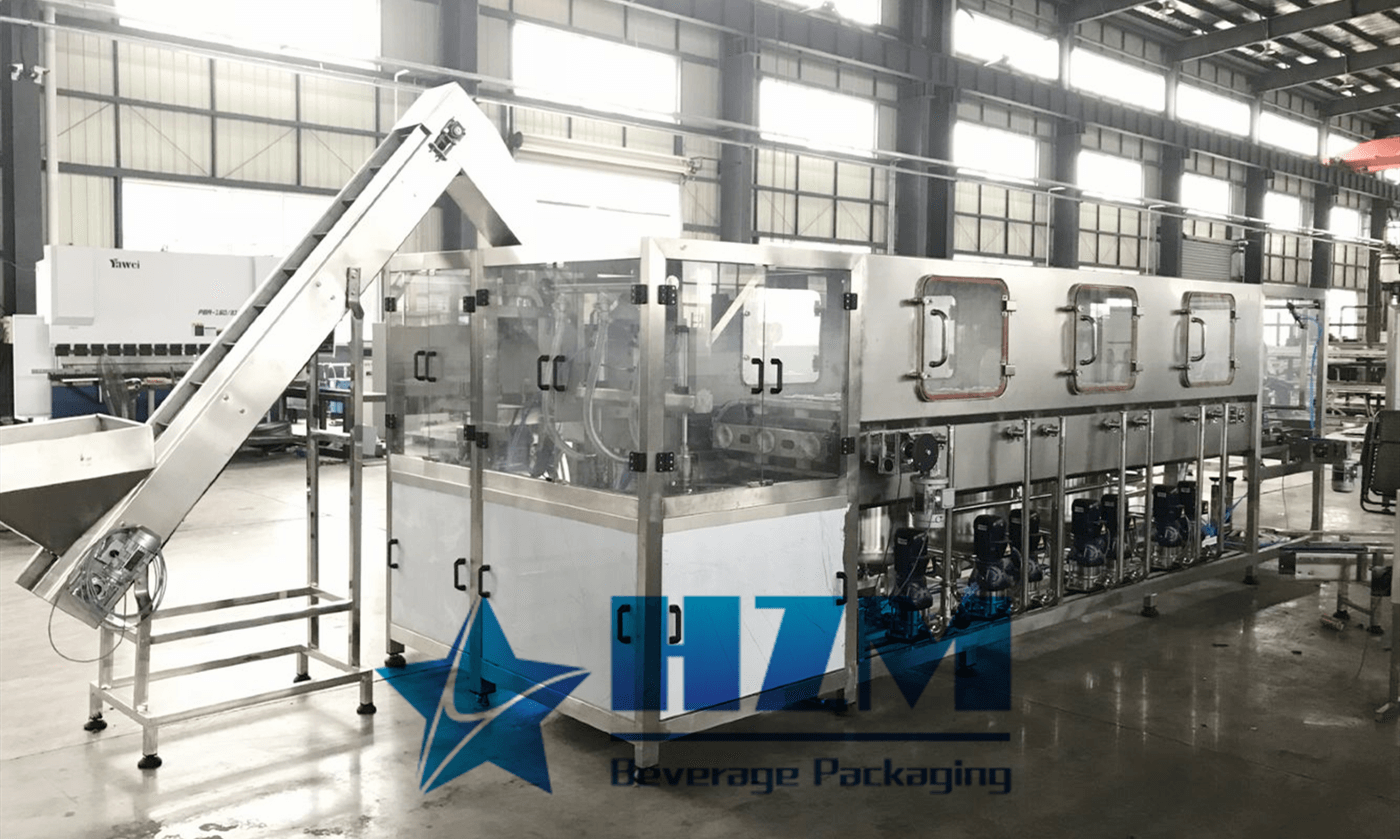

Bottle Washing Part

The pure water bottle is transmitted to the bottle washing machine by the conveying mechanism, and the bottle washing machine washes the inner wall of the bottle.

The bottle washer is equipped with bottle clamps on the rotary plate, which hold the bottle mouth and flip it 180° along a rail so that the pure water bottle mouth enters the bottle flusher downwards. In the specific area of the flushing machine, special nozzles spray flushing water to rinse the inner wall of the bottle. The bottle is rinsed, drained and then turned 180° along the guide rail with the bottle clamp holding it so that the bottle mouth is up. The washed bottles are exported by the bottle flusher through the bottle paddle star wheel and transferred to the filling machine.