Brief Introduction

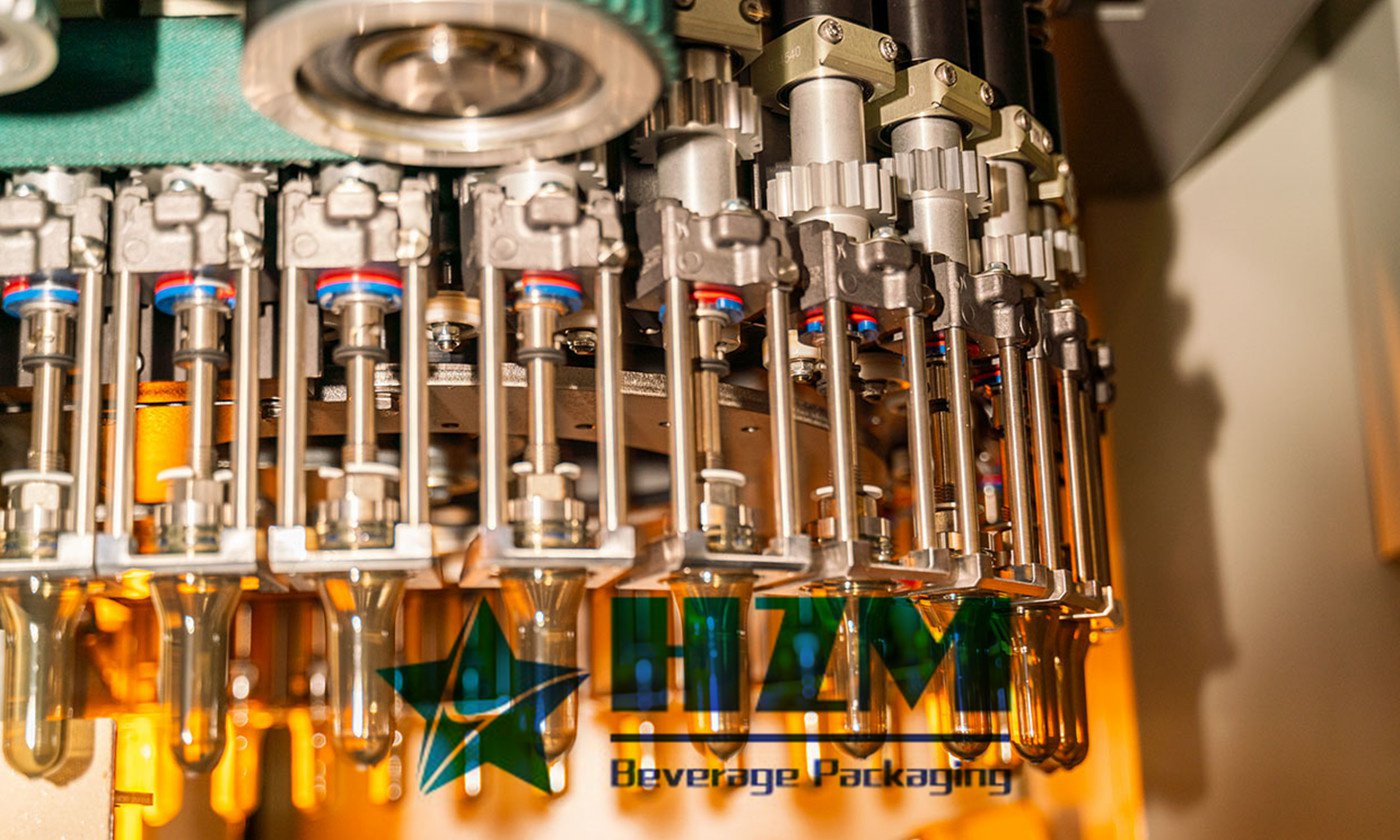

BGF full auto blowing-filling and capping machine is designed by us at the base of adsorbing international advanced technology. This machine is consisted of main blowing machine, heating stove, auto sending pre-form device, filling system, capping system, electrical controlling system and pneumatic controlling system. This type machine has characters of high degree of automation, stable specification, high efficiency manufacturing and low cost.

BGF full auto blowing-filling and capping machine has reached international level of same products, it is widely used in mineral water bottle、pure water bottle, soft drinks bottle, medicine bottle, food bottle and other PET containers.