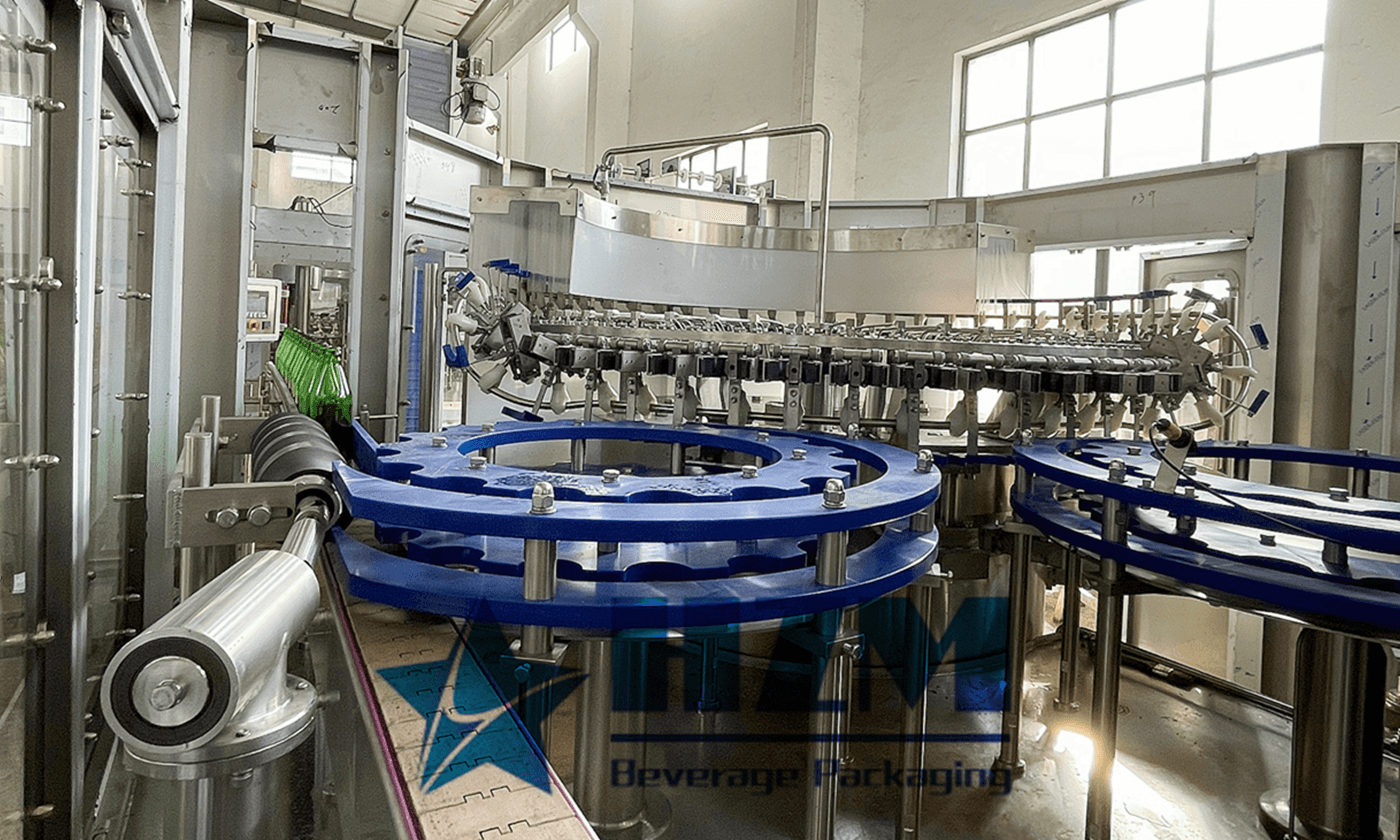

1. Bottles transmission adopts bottlenecks clamping technology, no need to adjust the equipment height when changing bottle volume, simply replace guide plate, thumb wheel that related to the bottle diameter and mouth.

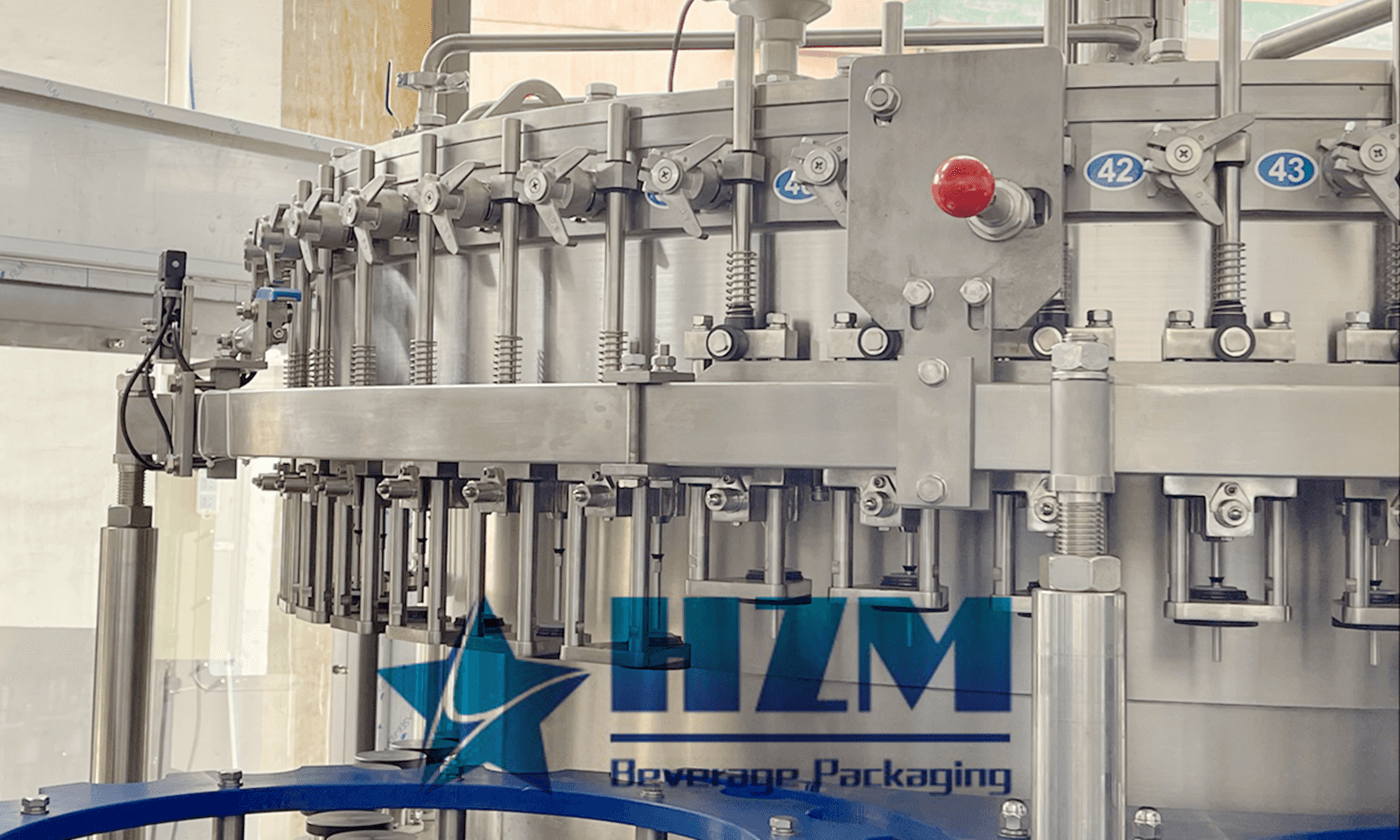

2. Valve opening device is driven by the cylinder; open the valve in time according to the signal, movements are accurate and reliable.

3. High-speed, high-volume, high precision filling valve, filling fast, accurate and non-liquid fluid loss.

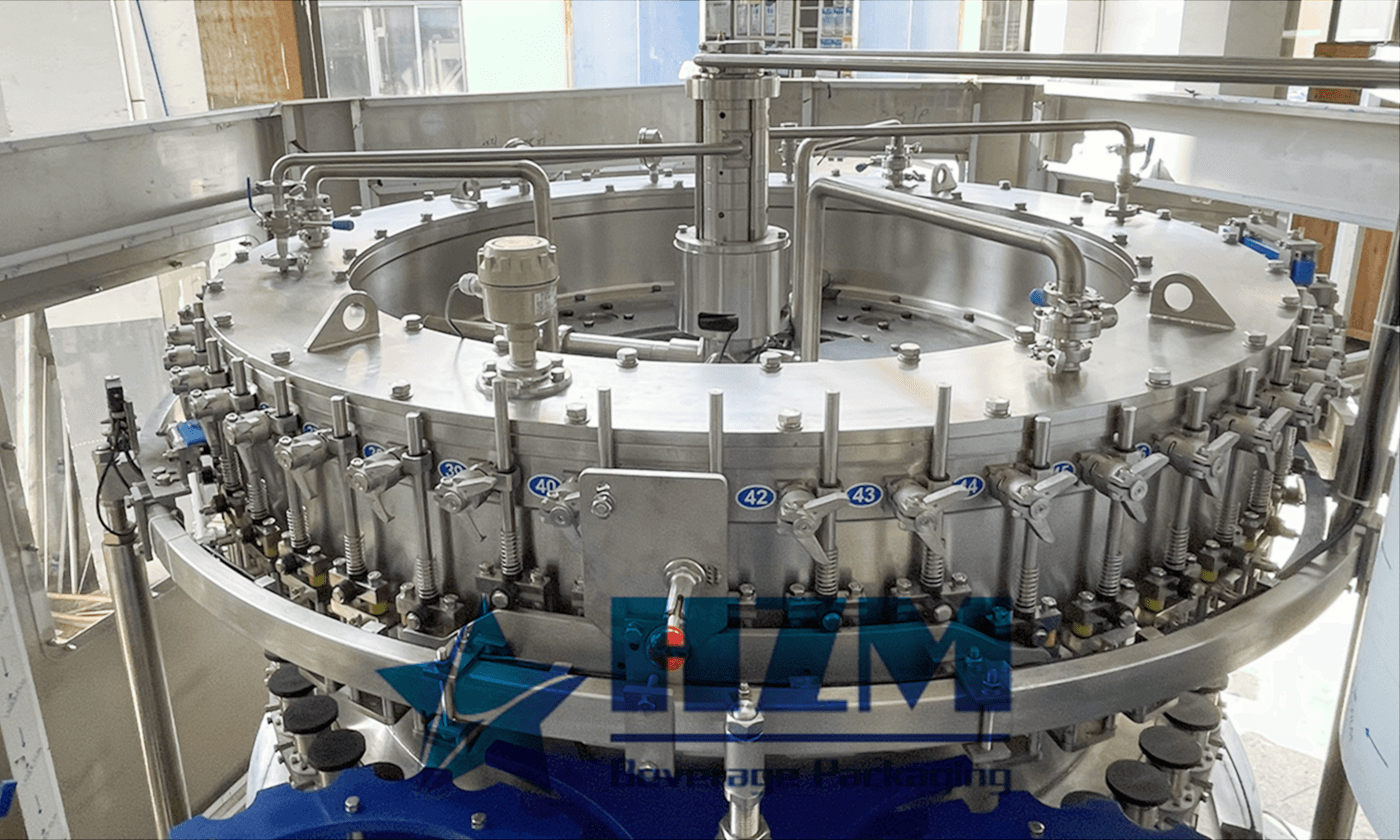

4. Using deflection regulating valve, continuous control of fluid materials flow, so that hydraulic cylinder to maintain a smaller level fluctuations, to ensure filling accuracy

5. Equipped with CIP circuit and control procedures, equipment is cleaned in place.

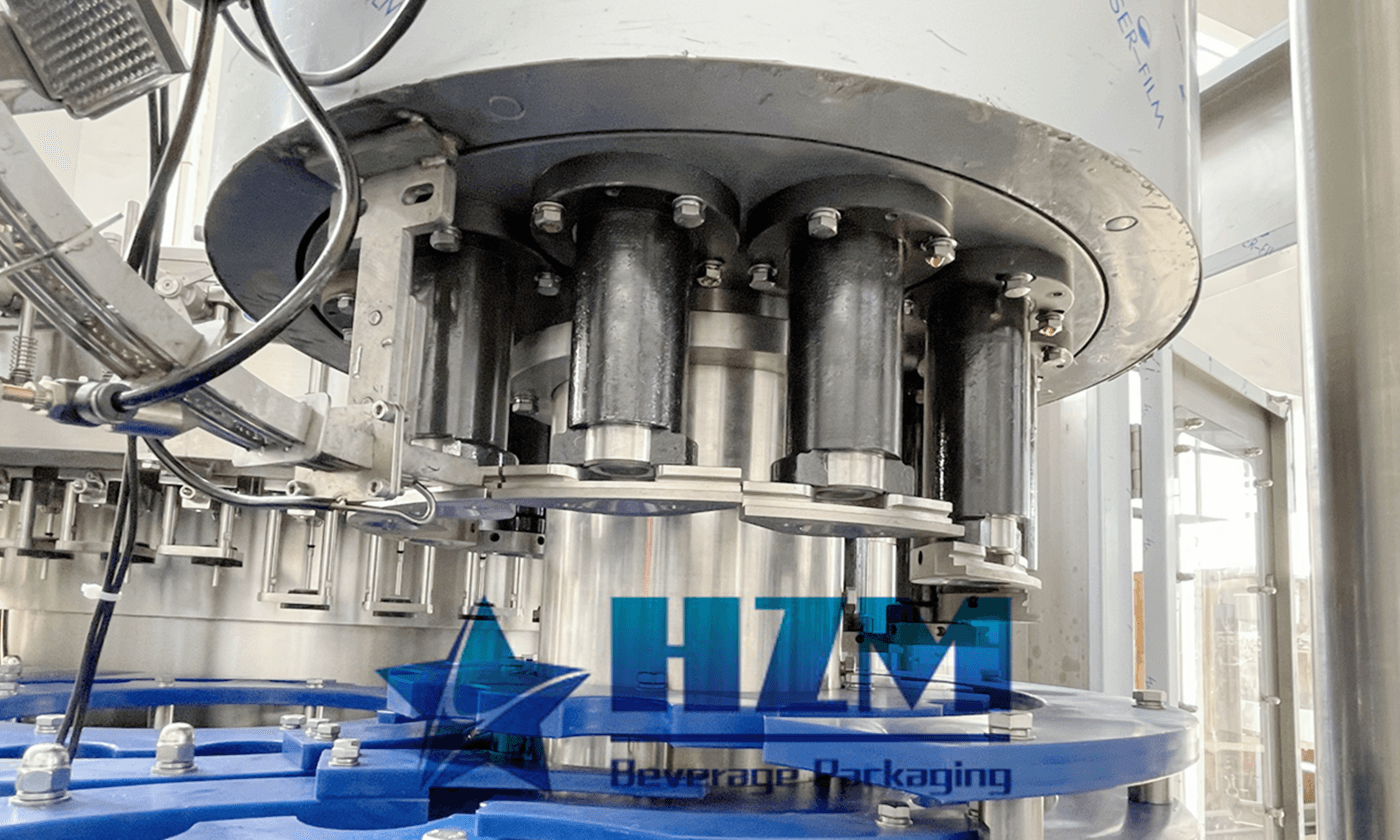

6. Capping head adopts constant magnetic torque device to ensure the seal of quality, and will not damage caps.

7. With complete overload protection device, which can effectively protect the equipment and the operator’s safety.

8. Main electrical components (touch screen, PLC, inverter, etc.) are imported brand-name products, OMRON, MITSUBISHI, SCHNEIDER,etc

9. Pneumatic system components are used well-known brand name products SMC/FESTO.