Brief Introduction

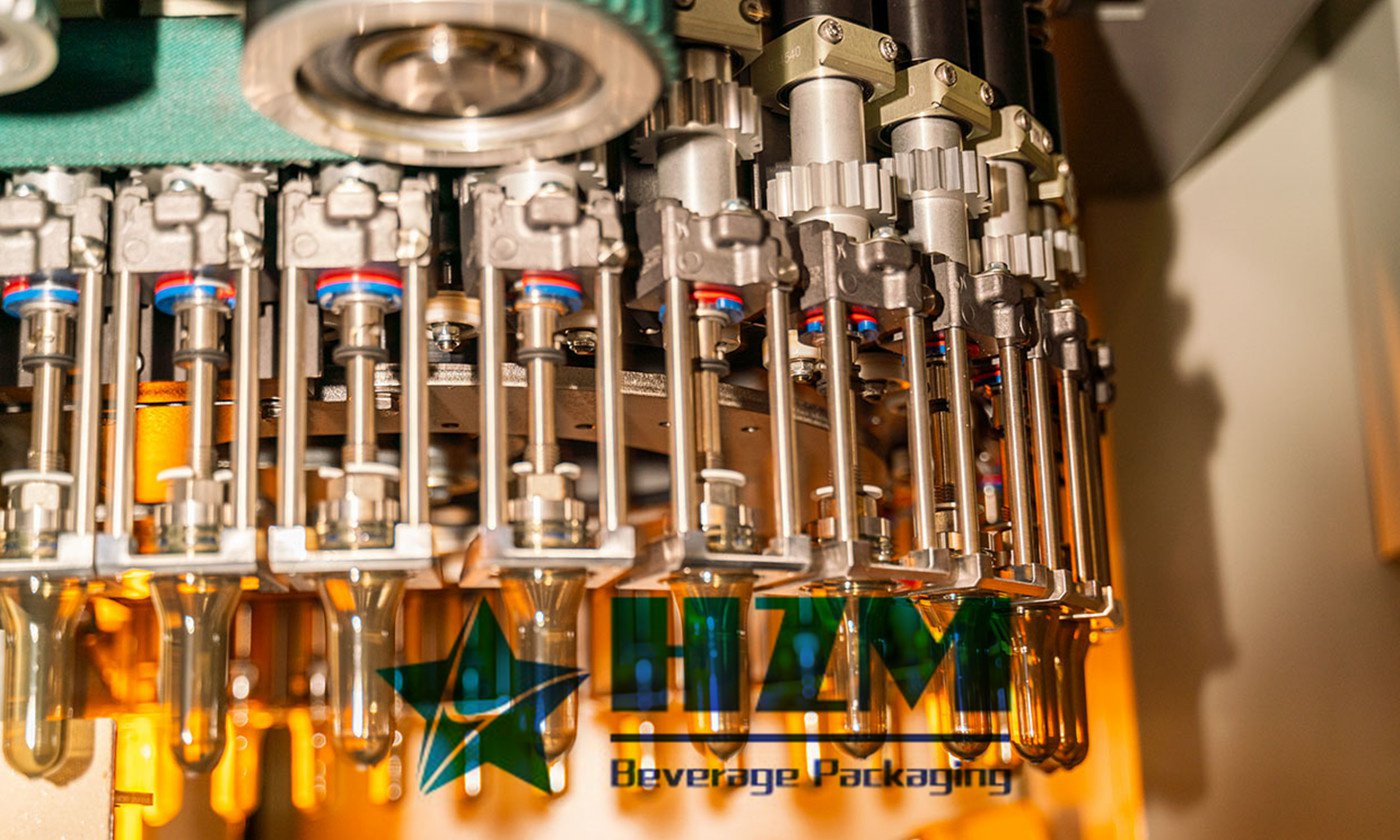

Automatic rotary bottle blowing machine is a high speed rotary bottle blowing machine which absorbs the most advanced bottle-making technology of today’s international. It is developed successfully by our company. This machine is consisted of rotary main blowing system, heating system, auto material sending device, electric control system and pneumatic control system. It has a high degree of automation, machine performance is stable and reliable, production efficiency is high and the cost is low.

It has reached the international level of similar products and it is widely used in producing PET containers like mineral water bottle, pure water bottle, and carbonated beverage bottle and so on.