Brief Introduction

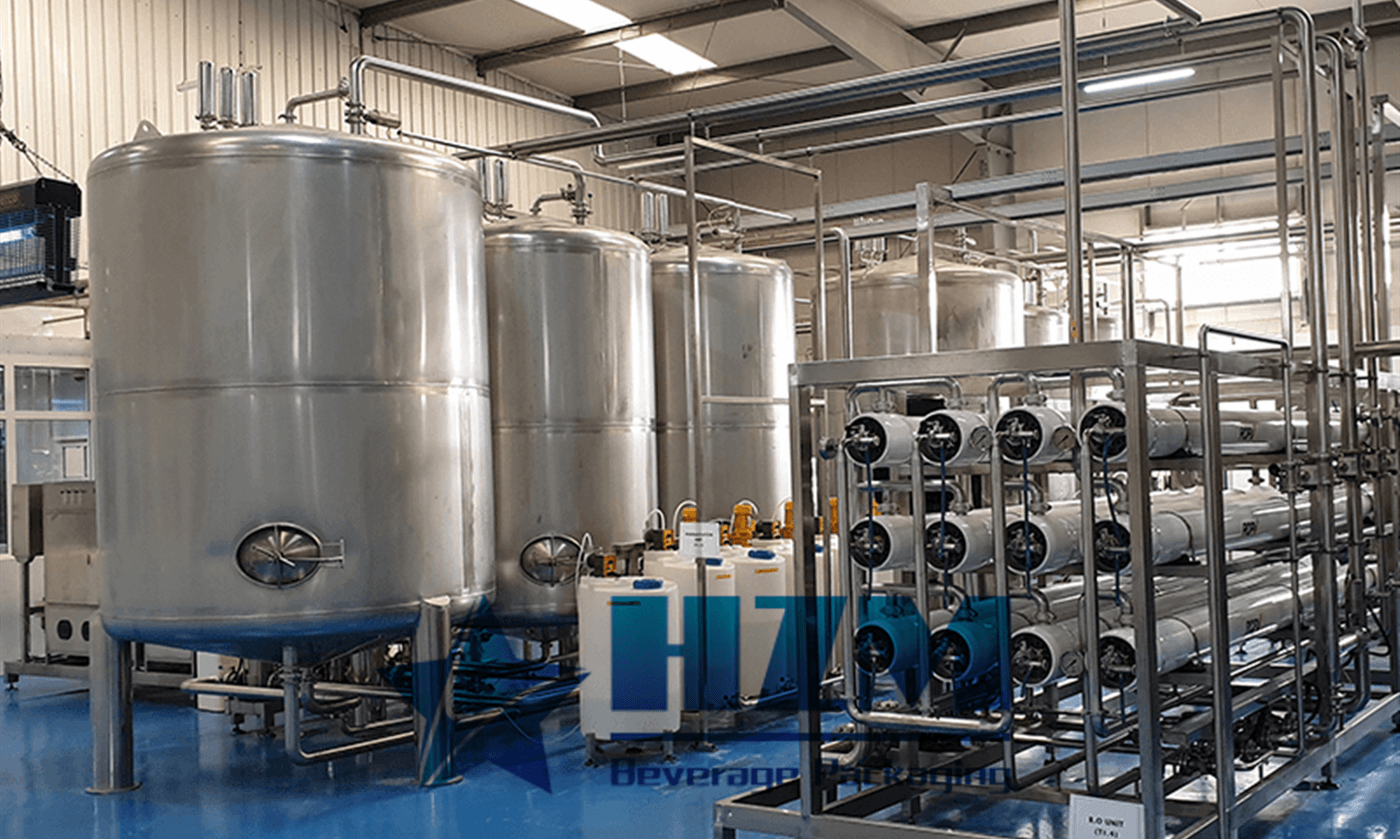

Water treatment purify system for mineral water, pure water and other water for food and beverage industry.It is mainly composedof the following equipment: pre-treatment system (water tank, multi-medium filter, active carbon filter, ion exchanger, millipore filter), membrane system (ultra filter, nanometer filter, RO system), electrodialysis device, sterilization system (UV&Ozone),pure water tank.,etc; The raw water can be ground water, sea water, tap water or other water source, we choose suitable purify system based on raw water analysis report.

The capacity usually from 1T up to 200T per hour. The process adopted for any set of water treatment system is depending on the quality of water resoureces and the purpose of water utilization. Any chosen process can basicaly be divided into three parts: pretreatment, advanced treatment, and terminal treatment. The pretreatment system is generally comprised of multi-media filters, active carbon filters, softener, Fe/Mn removal filters. Advanced treatment includes membrance processing and ionic exchange. The terminal treatment includes ozone, UV method, and mixed bed polisher EDI or CDI processing. The current water treatment system is mainly applicable to water supply for food and beverage production, fermentation and saccharification of beer, production of boiler feed, ultra pure water for electrical industry, and water for injection.