Brief Introduction

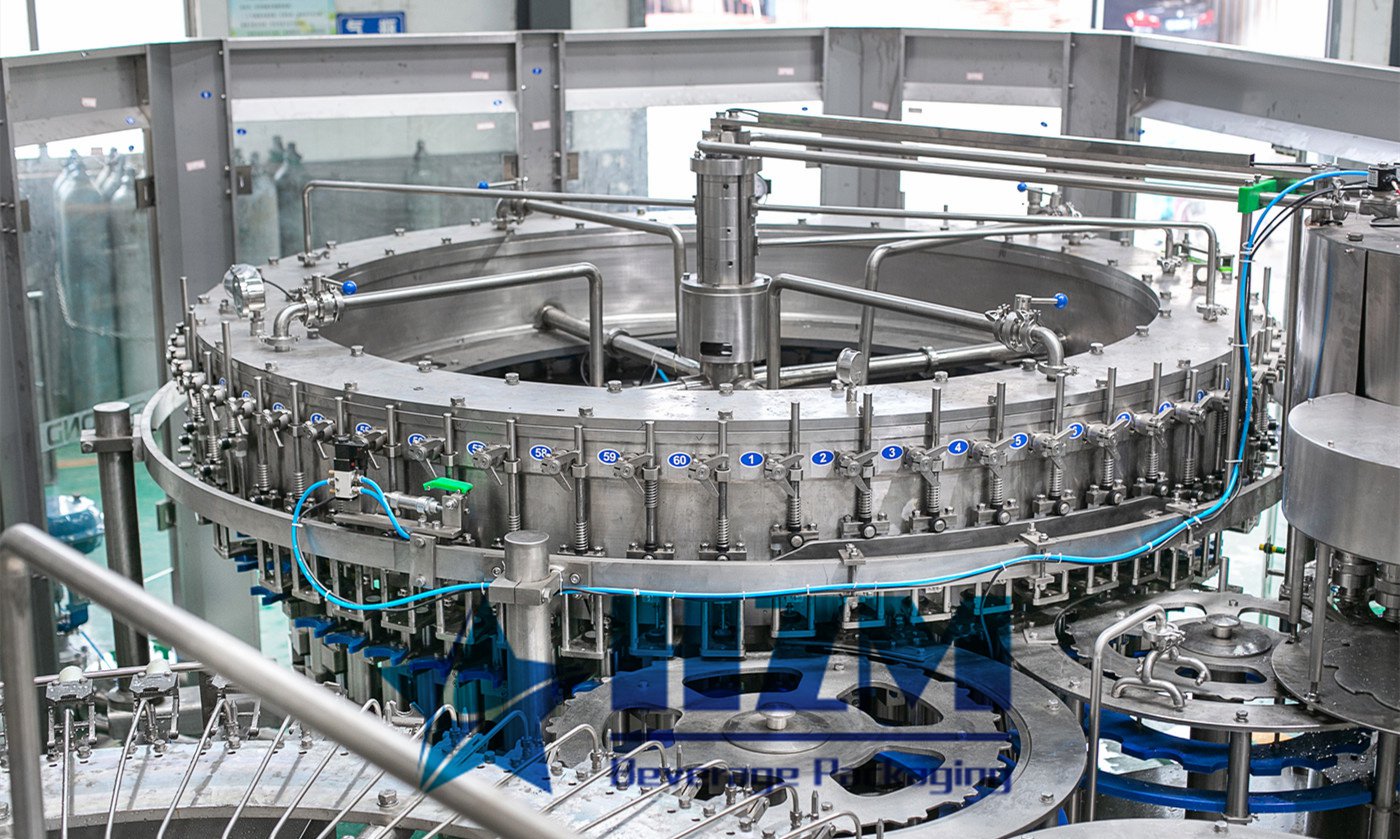

DXGF type soda water isobaric filling machine is 3-in-1 filling machine which combines rinsing, filling capping in one machine. The equipment is innovated and developed based on the introduction, digestion and absorption of foreign advanced technology and according to the gas-bearing beverage filling process requirements,. It is mainly used for gas flushing, filling and capping plastic pre-threaded cap soft drinks, cola, sparkling wine, mineral water, beverages etc. The machine has reasonable structure, safe, reliable, easy to maintain and it is the ideal equipment for beverage filling factory.