Brief Introduction

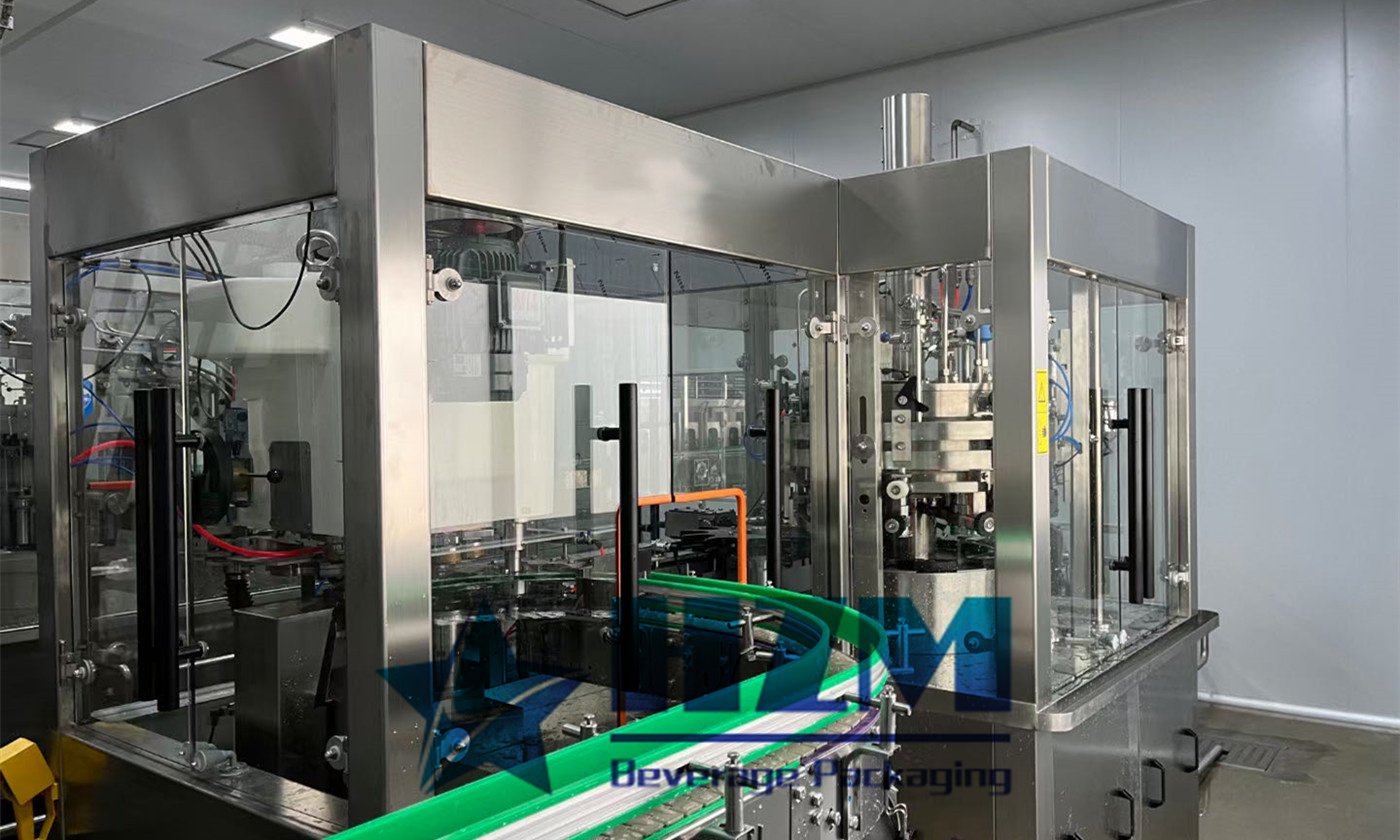

Craft beer can filling machine use rotary counter pressure filler-seamer system, it’s suitable for beer can filling and seaming. The technology of filling valve and control system adopt original technology of Germany, while seaming technology is that of Switzerland. The machine adopts advanced mechanical, electrical and pneumatic control technology.