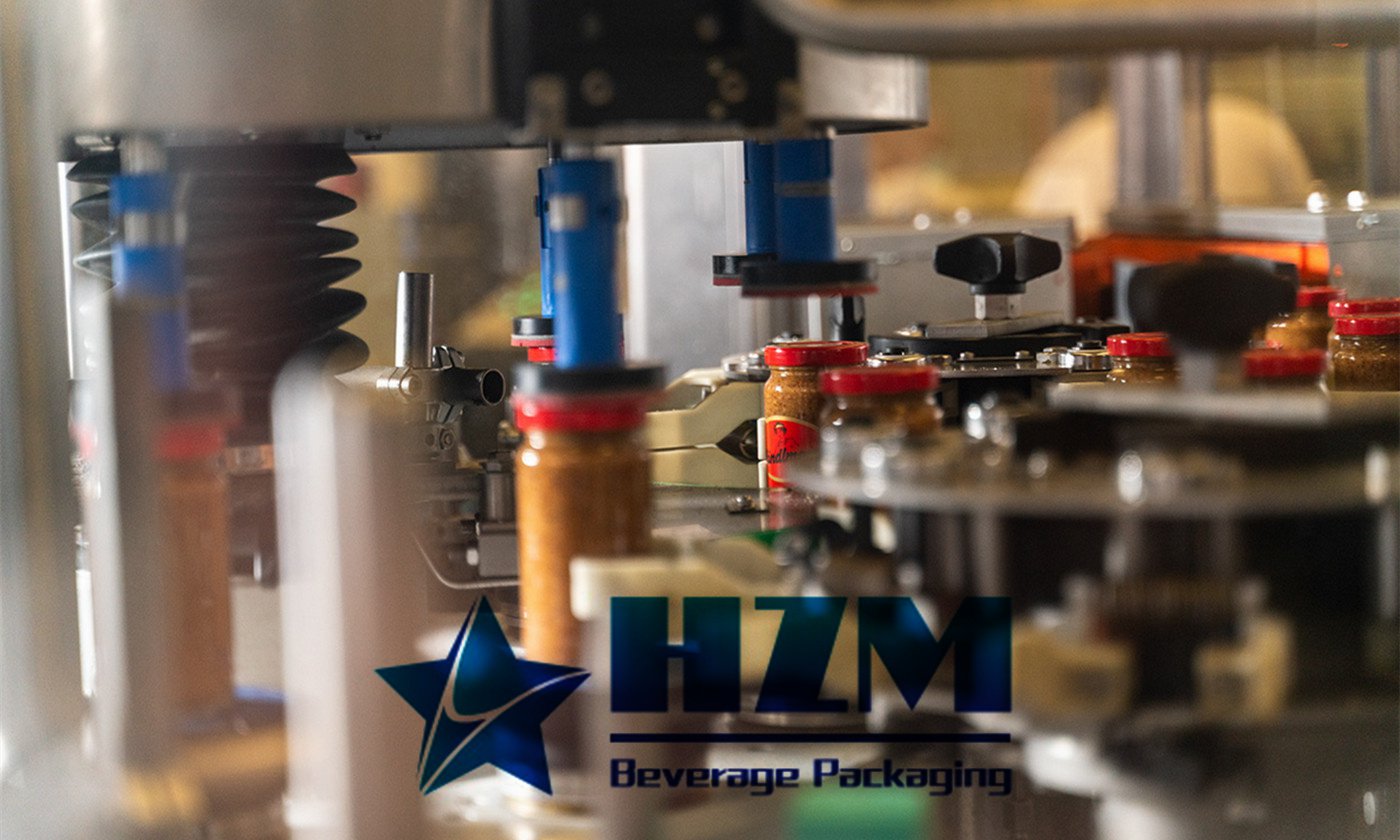

1.With inverter speed, be free to adjust the speed when the motor is running, labeling capacity is free to control.

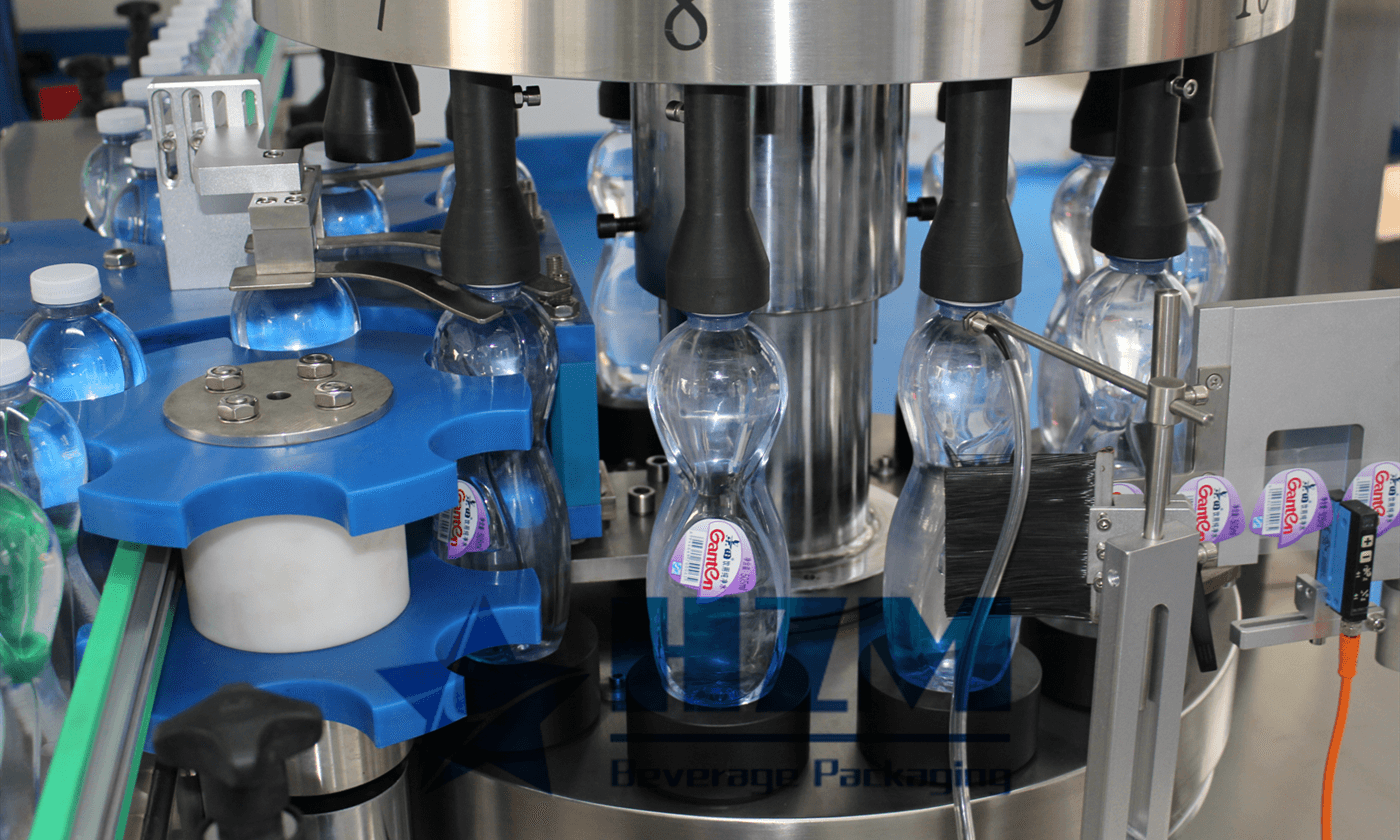

2.Automatic gluing, automatic calibration, automatic labeling, automatic photoelectric detection, high degree of automation, wide adaptation range, convenient adjustment, simple operation, attractive appearance, easy maintenance, cleaning.

3.Paste slot with stainless steel rollers with precision machining, glue as used with the check, and easy to clean.

4.Special rubber wheel by the number of road Process, not deformation, wear-resistant. On a the uniform thin plastic, glue amount of savings.

5.Pressure standard belt original Japan up to machines imported products, this belt core ply metal wire, and enhance the intensity of use, to avoid the phenomenon of thermal expansion and contraction and pumping of stomatal aperture changes other company products, stable pumping vacuum flow, thus ensuring stable conveying Label.

6.Labeling machine with PLC program automatic labeling process, compared with single-chip control actions achieve more stable, more convenient maintenance.

7.Machine processing precision and delicate, the basic components are standard accessories, convenient maintenance.